In the vast world of industrial valves, the triple-offset butterfly valve stands as a pinnacle of engineering innovation, offering a blend of precision, reliability, and efficiency. But what sets this valve apart from its counterparts, and how does it achieve such remarkable performance? Let’s embark on a journey to unravel the intricate workings of the triple offset butterfly valve and explore its functionality in detail.

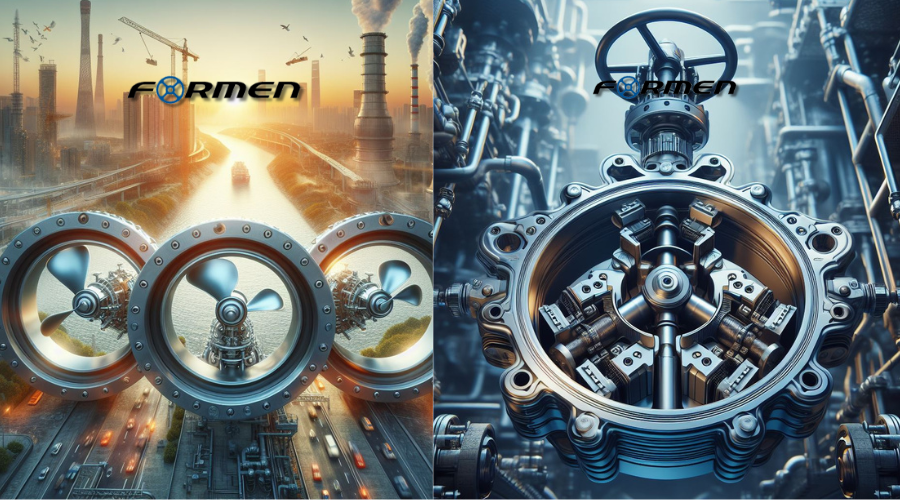

At its core, a triple offset butterfly valve is a type of quarter-turn valve designed to regulate the flow of fluids within pipelines. Its unique triple offset design distinguishes it from conventional butterfly valves, incorporating three distinct offsets to achieve a superior seal and enhanced performance.

First Offset:The first offset in a triple-offset butterfly valve refers to the positioning of the valve stem relative to the centerline of the valve body. Unlike traditional butterfly valves, where the stem is aligned with the centerline, in a triple-offset design, the stem is slightly off-center. This offset prevents contact between the valve seat and the disc during operation, minimizing friction and wear for smoother, more efficient performance.

Second Offset: Moving on to the second offset, we encounter the unique geometry of the valve disc. Unlike the symmetrical discs found in conventional butterfly valves, triple offset butterfly valves feature a disc with a conical or eccentrically tapered shape. This design lets the disc seal against the seat with minimal contact area, reducing friction and wear while ensuring a tight, reliable seal.

Third Offset:The third and most critical offset lies in the sealing surface geometry. In traditional butterfly valves, a soft elastomeric seat is used for sealing. However, the sealing mechanism takes a more advanced approach in triple-offset butterfly valves. The sealing surface is meticulously machined into a precise conical shape, which mates with a matching seat in the valve body. This metal-to-metal contact provides an exceptionally tight, bubble-tight seal, even under extreme pressures and temperatures, effectively eliminating the risk of leakage.

The triple offset butterfly valve represents a triumph of engineering ingenuity, combining advanced design principles with cutting-edge materials and manufacturing techniques to deliver unmatched performance and reliability. By delving into its intricate mechanics and understanding its inner workings, we gain a deeper appreciation for this valve’s role in ensuring the smooth, efficient operation of critical industrial processes across a diverse range of applications. Whether in oil refineries, chemical plants, or water treatment facilities, the triple offset butterfly valve is a testament to human innovation and the relentless pursuit of excellence in engineering.