Product Description

- The straight pattern body design

- Outside Screw and Yoke

- Bolted Bonnet

- Rising stem

- Loose disc, choice of plug or ball

- Renewable seat ring or Body seat ring

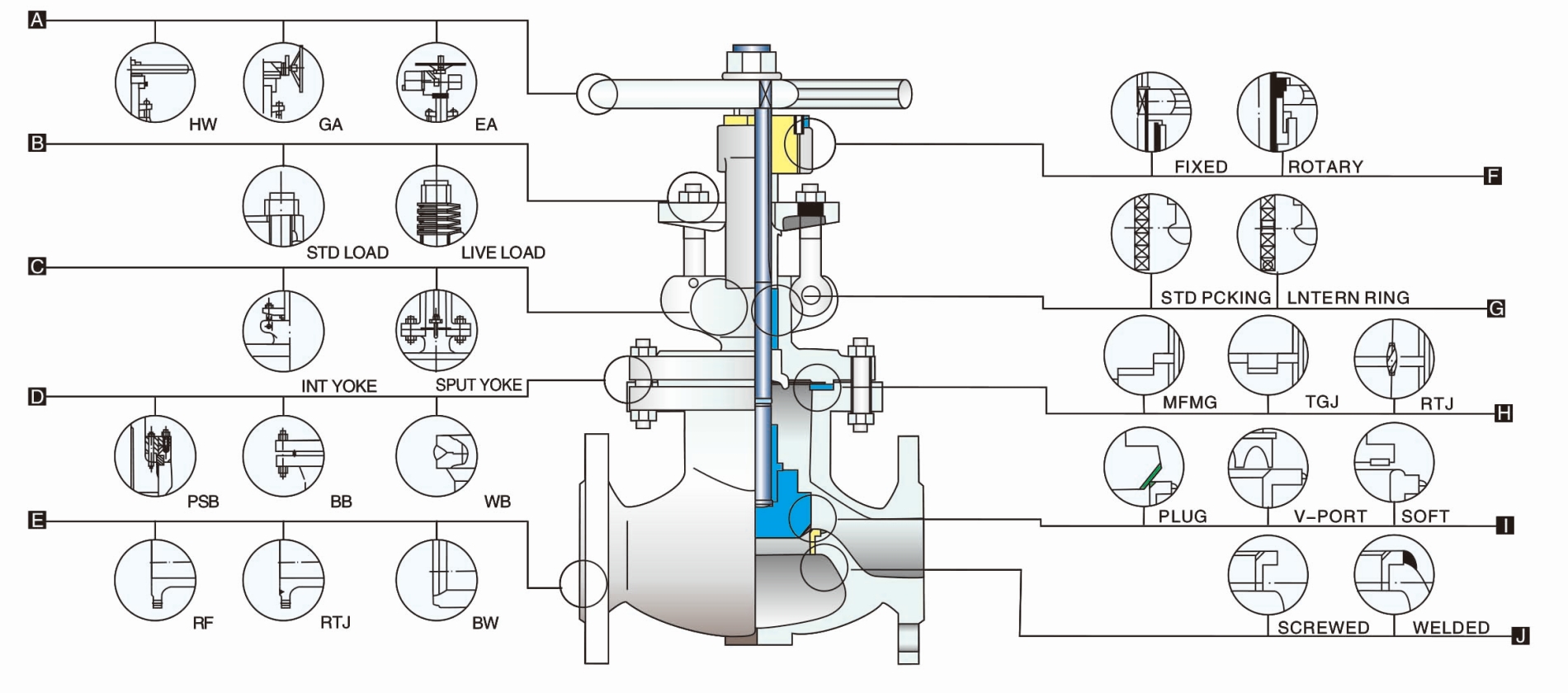

A OPERATION: handwheel, bevel gear, motorized actuator, and pneumatic actuator available for a specific application.

B PACKING LOAD: standard bolted packing load or live load with Belleville springs for application requiring frequent cycling o with high temperature and pressure variations.

C OS&Y: outside screw & yoke, yoke integral with bonnet for smaller size, split yoke for a bigger size.

D BONNET: standard bonnet bolted, welded bonnet for option.

E END CONNECTION: flange (RF, RTJ) o Butt-weld

F YOKE SLEEVE: Furnished in aluminum bronze to reduce operating torque. Most size furnished with ball bearing yoke sleeves.

G PACKING: lantern ring and double packing stack are available for critical service.

H BODY-BONNET JOINT: flat face gasket joint for 150lb valves; male and female joint for 300lb & 600lb; ring joint for 900lb & higher

I DISC: Plug disc is stem-guided for all sizes. Disc has a differential angle front the seat to provide linear contact for maximum sealing. The bottom of the v-port disc is guided by the body seat ring for maximum disc stability in throttling applications; the soft Teflon ring is excellent for lower temperature service were a tight shut off required.

J SEAT RING: Separate heavy-duty, full ported rings for easy maintenance. Screwed or welded connection into the body.

WHAT IS A GLOBE VALVE?

Globe valves are linear motion closing-down valves, where the member of the closure is moved squarely on and off the seat. The closure member is usually referred to as a disc, regardless of shape. The opening of seats varies in direct proportion to the disc’s travel. This proportional relation between valve opening and disk travel is ideal for duties involving flow rate regulation. Globe valves are best suited for throttling and fluid flow control and are generally used in small-sized piping. Formen valve as the top wholesale Bolted Bonnet Globe Valve manufacturer offers you fully customizedBolted Bonnet Globe Valve China anywhere around the world.

BOLTED BONNET CONNECTIONS

One of the easiest and least costly designs is the bolted (also called screwed-in) bonnet. The bonnet gasket, however, has to accommodate rotating faces, and repeated de-screwing of the cap can damage the joint faces. Also, for the higher size valves, the torque needed to tighten the bonnet joint is very big. We make premium quality bolted Bonnet Globe Valves which are according to international standards. We are the leading bolted Bonnet Globe Valve supplier of China.

FEATURES OF BOLTED BONNET GLOBE VALVES

- With a higher bolting torque, a more reliable, leak-proof body bonnet joint guarantees joint tightness.

- Body guide disks reduce side thrust and provide longer life for the discs, seats, and bodies.

- Handwheel impactor for the near shutdown.

- Frame made of forgings of superior strength, and optional cast steel.

- Velan stem seal provides tight sealing over long periods of time with little or no maintenance.

- Free Packaging Live-loading.

- Non-rotating bran.

- Firmly seated faces endure erosion.

- Disponible with seal weld provision.

- Other sizes available and the pressure groups.